The new KONFORT service station models offer an optional climate control efficiency kit module which allows ambient and vent temperatures to be measured.

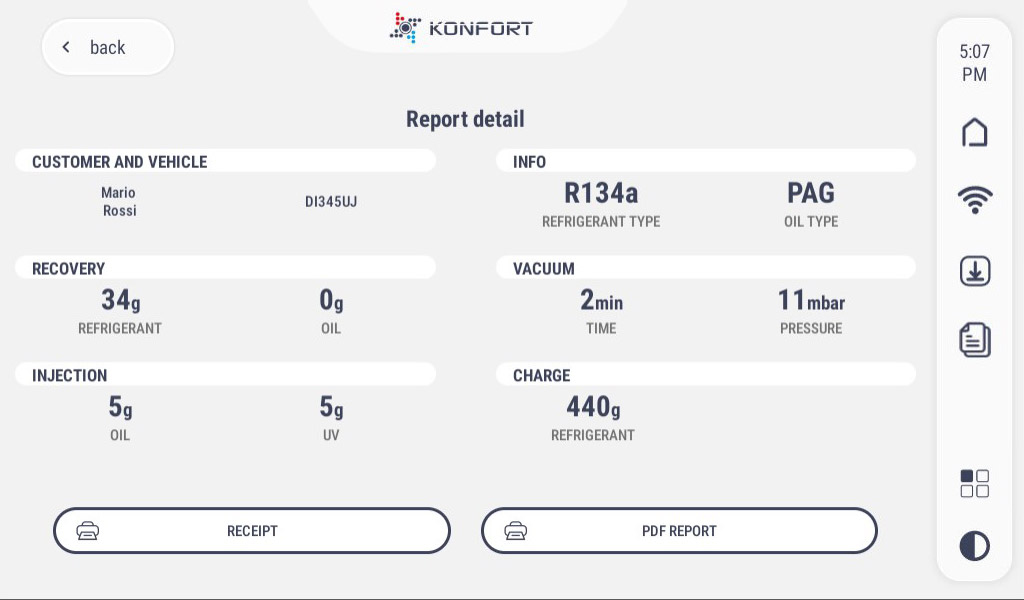

Once the test has been carried out, the KONFORT unit provides a detailed performance report.

Leave your email to stay updated on the latest news in the industry.

It is a mid-range model which boasts the typical technical features of the top-range models such as

It can be purchased in the R134a or R1234yf version.

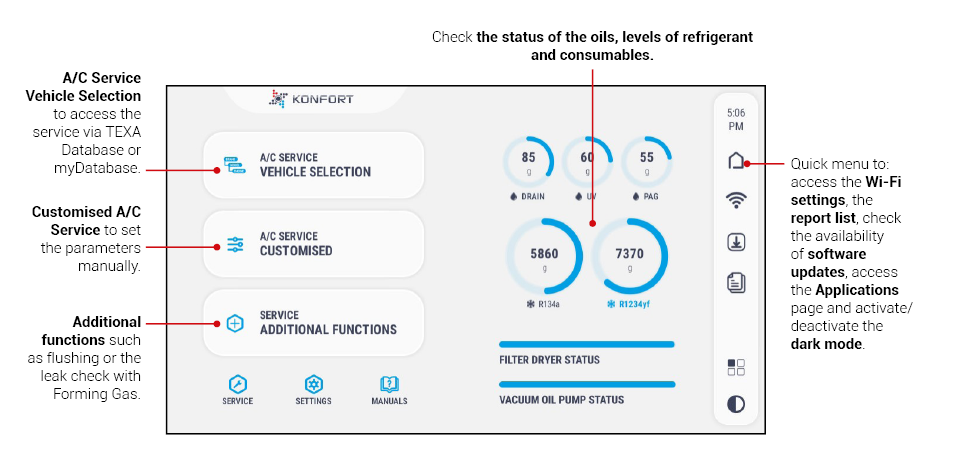

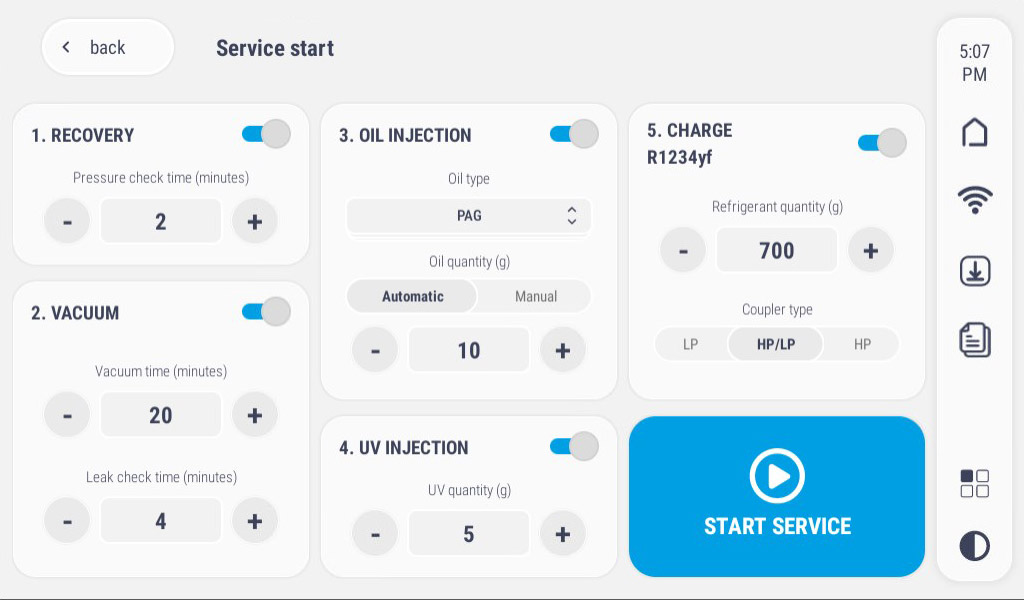

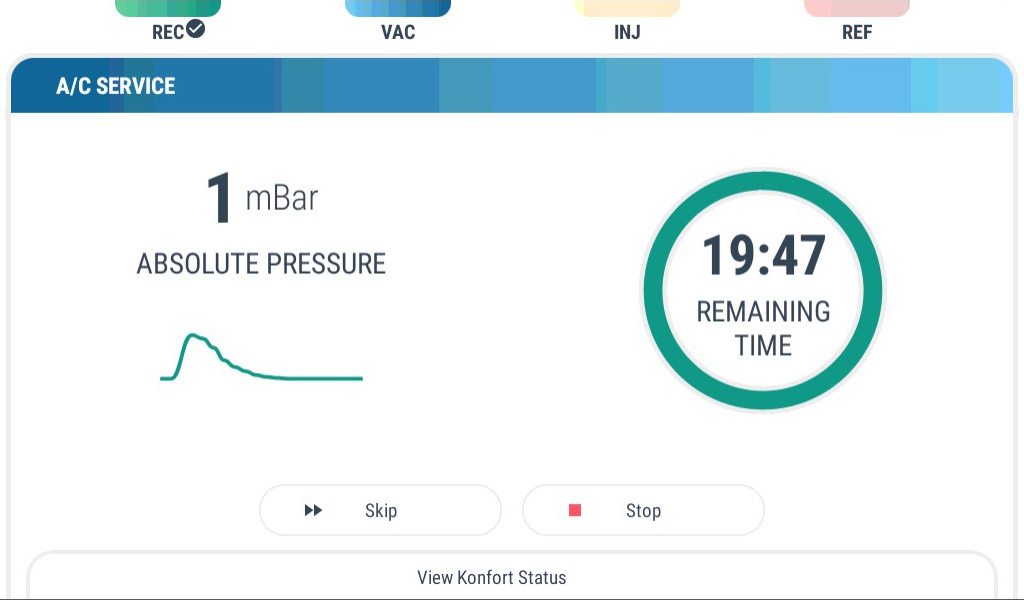

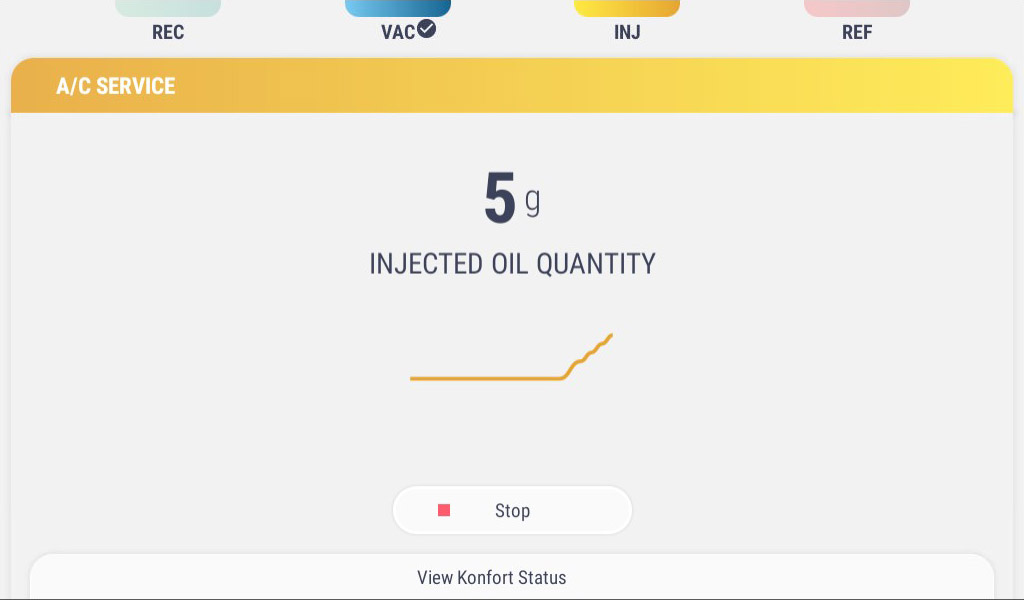

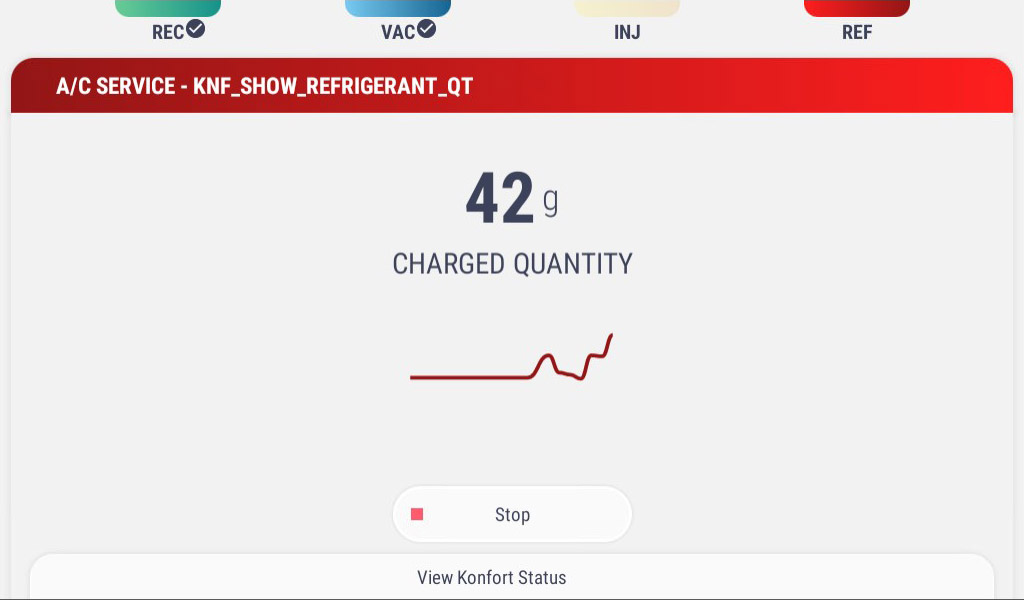

The KONFORT TOUCH charging stations are equipped with a 7-inch colour multi-touch screen display, which gives them great usability and allows always having a clear view of the operations to perform. Moreover, the innovative graphic interface has been developed to ensure a really intuitive software user experience, making it easier to quickly read the data displayed.

Data reading is best supported by the high resolution and nits brightness.

An interesting feature is also the possibility for the operator to choose between a light or dark theme

for the background.

The display on the KONFORT TOUCH stations features the glove-touch technology, which ensures perfect use while wearing different types of work gloves.

The great ease of use of the KONFORT TOUCH range and its smart approach also lie in the possibility to use

the Wi-Fi connectivity for a series of activities, such as:

– printing reports in A4 format;

– receiving software and firmware updates in real time;

– receiving remote technical assistance;

– connecting to the myTEXA portal;

– connecting with the KONFORT Mobile APP.

The Bluetooth module also allows connecting the stations with several accessories, such as the A/C efficiency kit.

The stations are also equipped with a practical USB port, which can be used to back up the reports of the services performed and the entire system. It is very useful also to install software updates if the workshop does not have a Wi-Fi network.

Besides the built-in thermal printer, KONFORT TOUCH allows printing the reports of the services performed also via Wi-Fi and in A4 format, using any printer connected to the workshop’s Wi-Fi network.

Thanks to a dedicated APP, the stations communicate with Android and iOS smartphones, so that operators can follow the progress of the service and charging procedures also remotely.

The technician receives a notification in case of faults and when the service is complete. The new APP also allows you to view and manage the performed maintenance services easily, even when the station is turned off.

The KONFORT TOUCH stations are designed to be extremely well-functioning and achieve the maximum

simplification of the maintenance and charging operations.

To reach this goal, the Android 10 embedded operating system is used.

This choice allows better familiarity in activating the various controls, with a very intuitive visual language

and an interface rich in infographics.

The software updates are performed automatically and securely.

The interface is designed to provide all the necessary information in a single screen; this way, users can have

direct access to the most useful operations. In next to no time, you will move from the initial station activation

phases to carrying out the service.

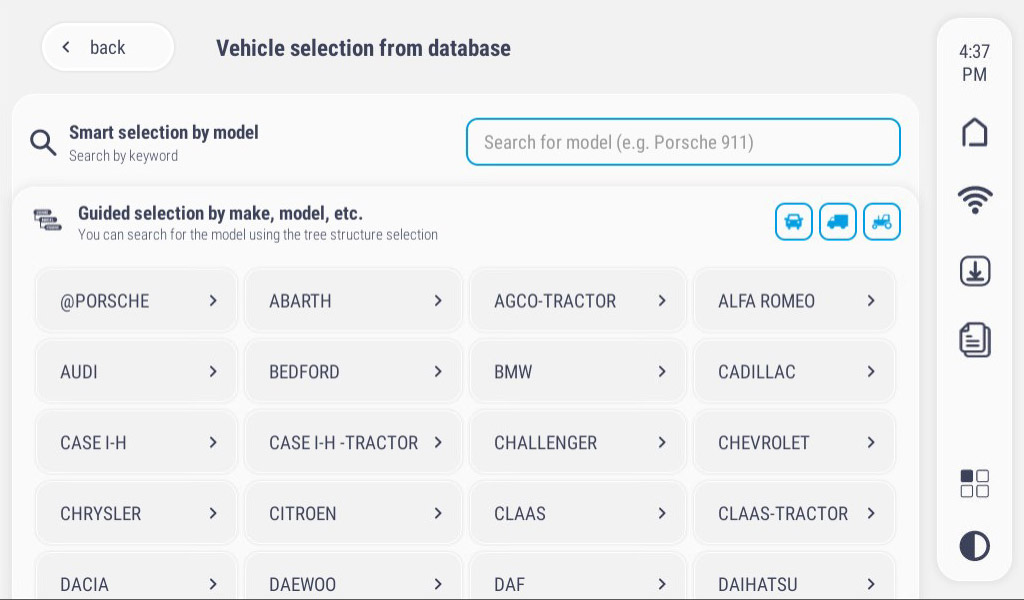

The menu, which can be browsed really easily, makes the most of the large display and minimises the “steps”

required to start a charging service. Moreover, the search mode “Smart selection by model” allows you to find

the vehicle you are working on by simply entering one or more keywords.

Below is an overview of the main software screens, from the service selection to the charging phases and the

remote after-sales assistance request:

The owner of a KONFORT TOUCH station can be sure not only to use a highly technological tool, but also to be able to count on constant after-sales assistance.

To use this service, simply connect the station to the workshop’s Wi-Fi network, access the Applications page from the software interface and select Remote Assistance.

From here, it is possible to ask for the help of a specialised technician who will take control of the KONFORT TOUCH remotely to carry out maintenance activities in support of the operator at the workshop.

For example, the technician can activate the station, check its operating status and any errors that it may have set, calibrate the scales, check the solenoid valves, and much more.

The KONFORT TOUCH models can be used in combination with a range of optional accessories that expand

their functionality and potentiality, such as:

The new KONFORT service station models offer an optional climate control efficiency kit module which allows ambient and vent temperatures to be measured.

Once the test has been carried out, the KONFORT unit provides a detailed performance report.

It allows solving quickly and efficiently any leak detection problems in A/C systems that use refrigerants R134a and R1234yf.

Using the kit is a strategic solution, since it allows identifying the smallest gas leaks with precision.

This is due to the molecular size of the Forming Gas, much smaller than any refrigerant.

It guarantees the safe evacuation of the refrigerant, whichever its nature.

It complies with the technical, performance and safety requirements of the most important vehicle manufacturers and allows recovering up to 95% of the refrigerant in the system. At the end of the recovery, the contaminated refrigerant can be drained into a tank and disposed of.

This device immediately identifies the type of refrigerant used in the vehicle, R134a or R1234yf, and checks its purity.

The entire operation takes approximately one minute. If the refrigerant is found to be unsuitable or contaminated, the station warns the technician and stops the operation.

It is possible to install a very useful thermal printer, to generate at any time an accurate report of all the operations performed.

Flushing is the mechanical operation carried out to clean the air conditioning system components of a vehicle. This includes: A supplementary 6lt capacity tank with a contamination indicator, a stainless steel filter which is easily removable for cleaning, 5mm diameter hoses flushing hose and universal adapter case

The KONFORT TOUCH range benefits from new developments in materials, technologies and automated

production procedures that resulted in TEXA gaining an ISO TS 16949 certification.

All phases are subject to strict quality control, from component selection and development to machining, assembly,

distribution and after-sales service.

After assembly, the stations enter the testing department where the electrical system is tested and the scales

sensors and pressure transducers are calibrated. Functional testing is then performed to verify that all components

and devices respond correctly and perform according to specifications.

Rigorous testing eliminates the risk of defects in the hydraulic system and ensures that all parts are effectively

sealed. The final stage of testing takes place in a special sealed chamber and involves the injection of helium into

the tank and the recharge circuit. Helium is used because its particularly small molecules are able to find even

minute leaks.

The KONFORT charging stations conform to European CE/PED safety standards, to the American standards

governing refrigerant purity (SAE J2099 for both R134a and R1234yf) and to those governing efficiency in the

recovery of at least 95% of used refrigerant (SAE J2788 for R134a and SAE J2843 for R1234yf).

TEXA believes offering customer training to be particularly important. Adequate technical competence and

the correct use of diagnostic tools are critical to the success of a workshop business.

The teaching methods used in TEXA courses are based on an ideal mix of theory and practical elements.

Practice plays a fundamental part, as it combines testing and simulations with use of the technicians’ own TEXA

diagnostic tools, thus stimulating a more active and dynamic participation and effective learning.

*Verify the availability of TEXAEDU in your own country.

Prodotto da inserire all’interno del sistema per il trattamento dei gas di climatizzazione di autoveicoli KONFORT.

Verificare con il proprio rivenditore TEXA di fiducia le modalità di accesso al Nuovo Piano Industria 4.0.

Display: 7” TFT IPS 1024×600 400CD

GPU: Qualcomm© Adreno™ 308 Graphics Processing Unit (GPU) with 64-bit addressing

Touch: Capacitive touch panel, USB/12C interface

CPU:

SC200R Series Snapdragon QCM2150 Quad-core

ARM Cortex-A53 64-bit CPU @ 1.3 Ghz

STM32F103 – ARM Cortex M3 32-bit CPU

RAM: 2 GB LPDDR3

Hard disk: 16 GB eMMC

Operating system: Android 10.0

Audio peripheral: devices 1 speaker CES-703116-28PM 8ohm 2W

Wi-Fi:

802.11a/b/g/n, 150 Mbps, STA/AP/P2P

2402-2480 MHz

5 Ghz

Bluetooth:

2.1+EDR/3.0/4.1 LE/4.2 BLE

2400-2483,5 MHz

RF power: 20 dBm

I/O peripheral: devices USB 2.0 x1

Primary battery: 3 V CR2032

Secondary battery: NiMh 2,4 V – 600 mAh

Fluid / Group:

R134a / 2

R456a / 1

R1234yf / 1

Electronic refrigerant scale (Precision) [g]: ± 10

Electronic oil and UV tracer scales (Resolution) [g]:

1 (only oil drain)

Pressure transducer: Kl. 1.0

High pressure gauge [mm]: Ø 80

Low pressure gauge [mm]: Ø 80

Tank capacity [kg]: 10

Service pipes’ length [m]: 3

Filter assembly: 1 combined filter + mechanical filter

Compressor (airtight) [cc]: 12

Vacuum pump: 100 l/m, double stage, final pressure 0,03 mbar

Ambient temperature sensor (Resolution) [°C]: 1

Refrigerant purity [kg]: 150 (SAE J2099)

Recovery efficiency: > 95 % (SAE J2788 / SAE J2843)

Maximum operating pressure (PS) [bar]: 20

Safety device calibration [bar]: 20

Power supply voltage [V]: 230

Frequency (Hz): 50 (50 / 60)

Power [W]: 770

Operation temperature (TS) [°C]: 5 ÷ 40

Storing temperature [°C]: – 25 ÷ 60

Dimensions [mm]:

H: 1101

L: 598

P: 706

Weight [kg]: 90

Leave your email to stay updated on the latest news in the industry.