- Company

COMPANY

TEXA IN THE WORLD

Leave your email to stay updated on the latest news in the industry.

- Products

PRODUCTS:

SOFTWARE:

SERVICES:

- Sales Network

- Download

- News

LATEST NEWS

- e-Powertrain

Leave your email to stay updated on the latest news in the industry.

Designed to guarantee safety and comfort while driving, the ADAS (Advanced Driver Assistance Systems) are ever more common in latest-generation vehicles.

Cameras, radars, LIDARs and sensors must be recalibrated when replaced, but even when actions that affect them are required, such as: replacing the windscreen and bumper, repairing the suspensions, aligning the wheels, changing the tyres, replacing the engine control unit, etc..

Knowing how to intervene in this field is strategical to keep pace with the times and be able to offer customers first class assistance.

TEXA helps repair professionals operate on these sophisticated active safety devices, with a complete multibrand offer that includes:

TEXA’s solutions allow performing static and dynamic calibrations and resetting the ADAS correctly, guaranteeing the safety of the drivers and of who carries out the diagnosis and calibrations.

guides mechanics step-by-step throughout all the phases, thanks to the helps sheets specifically developed for each vehicle, offering a very wide CAR, TRUCK and BIKE coverage, at least 30% higher compared to other solutions on the market.

In case of any doubt or question on the calibration procedures, TEXA offers an ADAS Call Center line: a quick, competent and accurate contact to respond to any need. The service is included in the subscription to TEX@INFO Car Call Center*.

* Service currently available for the Italian market

For the calibration of radars, lidars, cameras and sensors, TEXA has designed and engineered RCCS 3 EVO, a top of-the-range solution that includes the best production technology and exceptional components.

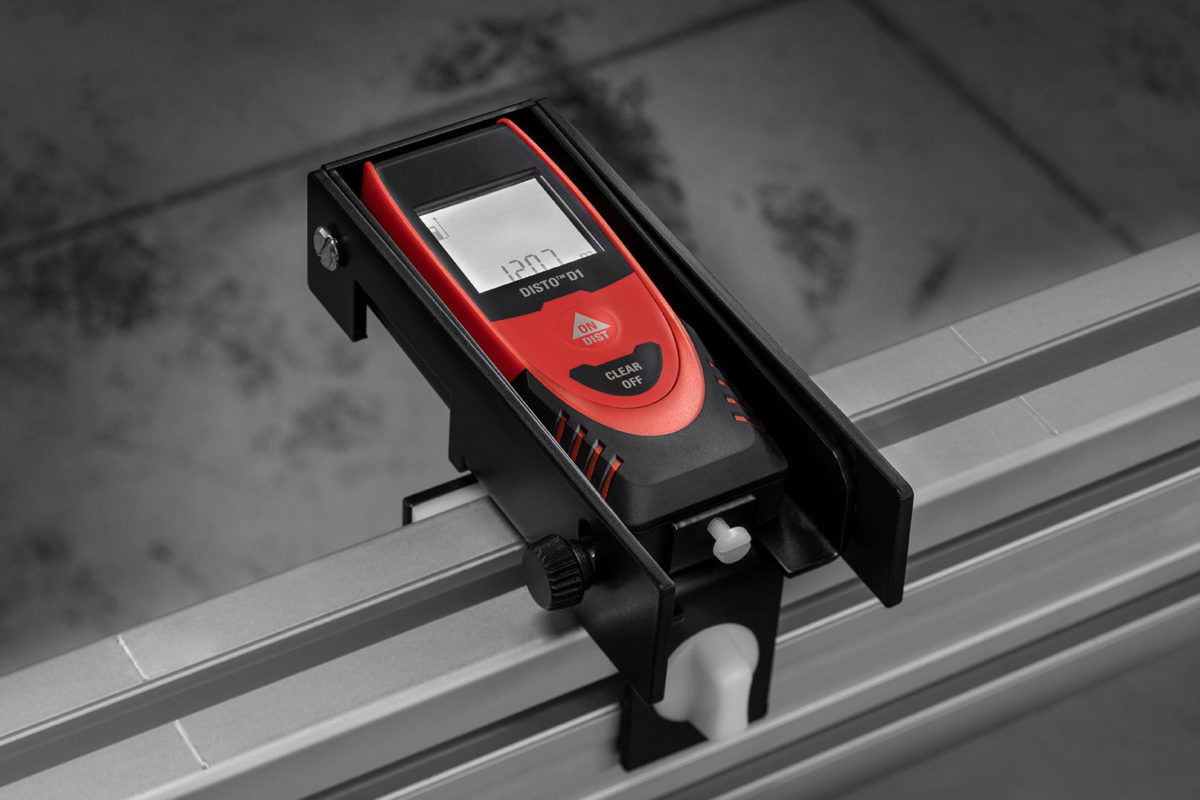

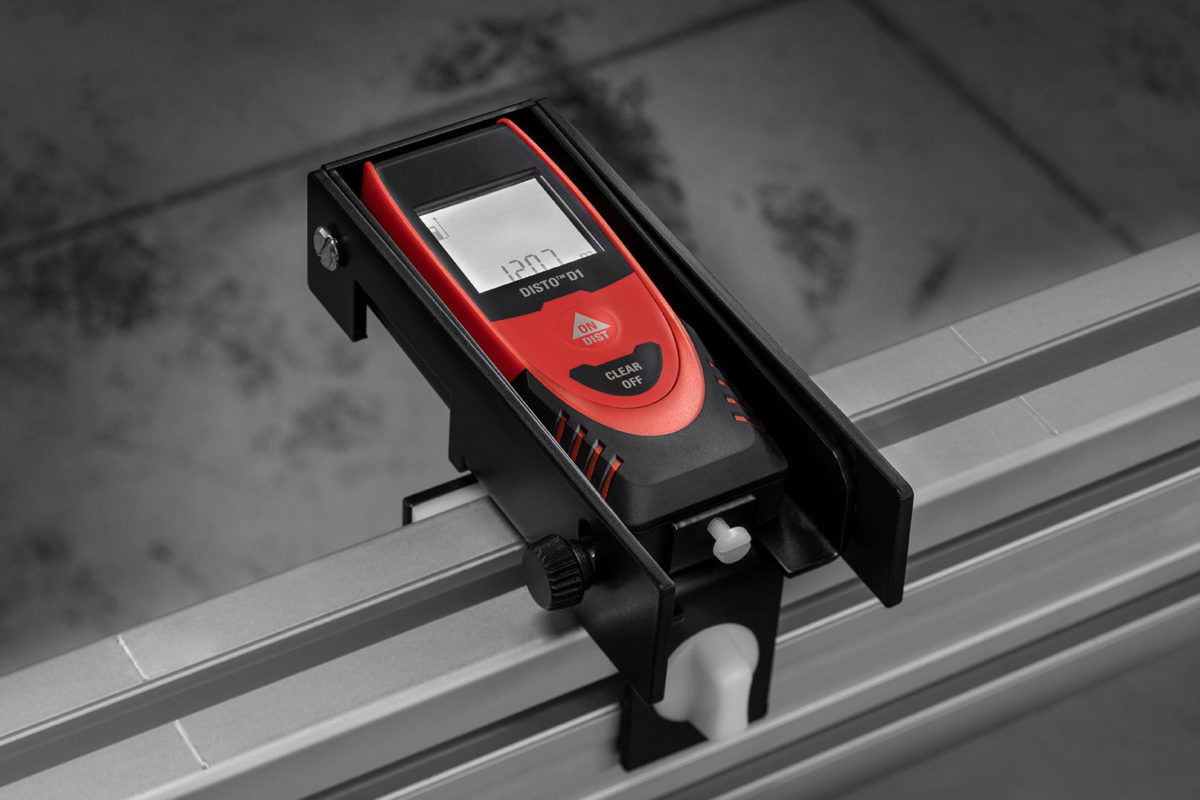

The version allows a wide range of possibilities of use: it can be used with the toe and thrust axis check kit, or in optical alignment mode. The Bluetooth distance measurers, which can communicate directly with the IDC6 software, make sure the unit is positioned properly by means of a guided procedure.

Thanks to the great ease of use and accuracy of the RCCS 3 EVO system, you can work in an even more simple and precise way guaranteeing the accuracy of the final result and maximum safety both for the driver and for the technician performing the calibrations.

Furthermore, it is important to highlight that it does not deform nor resize the images.

This way workshops are sure to operate in the most proper and safe way, without risking to alter the vehicle’s behaviour on the road.

Thanks to continuous software updates that each time offer new vehicles and eventually new panels, and to the essential help sheets edited per make and model, users are sure to complete any operation with maximum precision and to the highest standards, relying on an extraordinary coverage.

An actual Mini PC built into the unit, installed in the version RCCS 3 EVO with Monitor, guarantees the use of an intelligent system that synchronises the ICD5 software and the TEXA unit perfectly.

The images of the panels are transmitted and positioned automatically, based on the vehicle selection made. They are displayed through a linear, safe and quick process.

RCCS 3 EVO is made up by a very robust main support, which height can be adjusted thanks to its electrical operation. Using practical knobs, it can be easily tilted to the side and forward.

Furthermore, a knob allows even millimetric side movements. There is another laser level at the top of the unit that is useful for locating the centre of the vehicle simply by pointing at its front logo.

The horizontal adjustment bar is equipped with two distance measurers and a reflecting plate, the latter with a central laser for the front radar’s aiming.

RCCS 3 EVO is much easier to move around the workshop thanks to its new oversized castor wheels.

This technological equipment allows positioning RCCS 3 EVO and aligning it correctly with respect to the vehicle and to the ground easily, with absolute precision and in complete safety.

Other than the version with toe and thrust axis check, RCCS 3 EVO is also available in the highly performing optical alignment mode. This configuration uses wheel clamps and was designed to complete all the operations on radars and cameras in a quick and precise way.

Latest generation laser technology

The Bluetooth distance measurers provided by TEXA are the ideal solution to meet the most severe professional and precision criteria requested by workshops worldwide.

Thanks to a clear and precise messaging system all the vehicle preparation phases are extremely easy and quick.

The POSITIONER management software will guide the operator step by step to position the RCCS 3 EVO unit safely.

Below there is a practical example of positioning the unit using the dedicated software:

CCS 2 Dynamics is the transportable solution by TEXA for the calibration of cameras on cars, light commercial vehicles and heavy-duty vehicles. CCS 2 Dynamics is characterised for being compact, stable, easily disassembled and transported in a small-sized van. CCS 2 Dynamics can be configured in two versions dedicated to the CAR and TRUCK environments with specific accessories.

The Bluetooth distance measurers, capable of communicating directly with the IDC6 software, guarantee a correct positioning through a guided procedure.

CCS 2 Dynamics is equipped with four castor wheels that guarantee a fast positioning, and it can be stabilised thanks to its practical feet. In the CAR configuration it can be adjusted in height, longitudinally and horizontally.

In the TRUCK version, it can be adjusted horizontally and axially.

For camera calibrations, TEXA offers a large range of specific targets and accessories that can be perfectly integrated with RCCS and CCS.

Explore all the advanced features

of CCS2 DYNAMICS

The TEXA device has been specifically designed for the motorcycle manufacturers that equip their vehicles with rider assistance systems. It is an innovative tool that aims at ensuring the utmost accuracy when calibrating the radar systems.

The solution includes adjustable stands, mounting brackets and laser pointers, thus making up an advanced system that provides a complete package to carry out the calibration of the ARAS in a quick, precise and safe manner.

CCS (Camera Calibration System) is designed to create the best combination according to your operational needs. It is made up by a robust support on which the several panels divided by make are to be positioned.

CCS can also be used with a graduated mat and two supports to centre the wheel axle through laser levels.

The manufacturing features of the Kit make it a basic solution that is extremely easy to use, handy and easy to carry, even outside the workshop.

CCS is perfect for those technicians who cannot permanently dedicate an area of their workshop only to the calibration of cameras: in fact, once the operations on one or several vehicles are complete, all the equipment can be disassembled and easily stored in a small space.

TEXA’s ADAS solutions can be used in combination with other optional devices to work in depth on other electronic driver assistance systems, among which:

The IDC6 software was created by TEXA to guide technicians throughout the entire diagnostic phase in a simple, quick and intuitive way.

Drawing from over thirty years of know-how IDC6 has proved to be an essential aid for daily challenges, offering everything you may need.

The TEXPACK subscription is an annual service that allows using the tool to its full potential always being updated with the latest news on the market and coverages of makes and models.

All the diagnostic solutions subscribed to with TEXPACK have access to the functions with artificial intelligence

With the TEX@INFO services your basic subscription can be integrated with specific functions that can support you even more thoroughly in diagnosis based on your operating needs.

Leave your email to stay updated on the latest news in the industry.